|

|

Caterpillar 3406E Inframe-Overhaul Engine Rebuild Kit (FP Diesel)

- Availability:

- OEM Number:

RP984665

- Brand:

FP Diesel

This item ships for free (US only, excluding AK & HI)

Please choose your customizations:

| Kit Type: |

|

* denotes required field

Main Bearing Sizes*

You must select an option for 'Main Bearing Sizes'.

Rod Bearing Sizes*

You must select an option for 'Rod Bearing Sizes'.

$3,561.60

Price may change upon customization above.

WARNING: Cancer & Reproductive Harm - www.P65Warnings.ca.gov WARNING: Cancer & Reproductive Harm - www.P65Warnings.ca.gov

Fast Shipping

With warehouses

across the US, we ship quickly and efficiently.

Expert Advice

Expert tech advice

before and after your purchase.

High Quality Parts

Our parts meet

and exceed the OEM specifications.

Details:

Parts Included in Inframe Rebuild Kit

(6) Liner Kits (Sleeve/Liner, Piston, Rings, Wrist Pin, Liner Seals)

(6) Rod Bearings

(1) Main Bearing Set

(1) Upper Gasket Set (Includes Injector Cup Seals and Valve Stem Seals). Note - Injector O-Rings are not included.

(1) Oil Pan Gasket

Liner orings included in this engine kit are color coded.

There will be 3 O-Rings and a Filler Band. This is the order from top to

bottom: Black (Filler Band), Green, Orange, Blue/Purple.

Cylinder blocks must be precisely checked for concentricity and deck surface condition prior to liner installation. Anything less than perfect condition at these points can lead to cracked flanges on the cylinder liner. Failure to thoroughly inspect these two areas is the leading cause of liner flange cracking and should be the foremost consideration if liner flange failure occurs. 100% of FP Diesel liners are magnufluxed prior to shipment. CLAIMS SENT TO FP DIESEL INVOLVING CRACKED CYLINDER LINERS WILL NOT BE CONSIDERED WITHOUT SUFFICIENT EVIDENCE AS TO CYLINDER BLOCK CONDITION.

For cylinder block deck inspection criteria and proper liner protrusion refer to the appropriate OEM service information or the OEM block joint repair procedure (SEHS9564-1). All FP Diesel hardened liners are coated with a rust preventative during packaging. Each liner must be cleaned of this coating and then dried before placing it in the cylinder block. The liner should be cleaned with soap, warm water and a bristle brush taking extra care at the seal ring groove and filler band groove areas. Carefully dry with compressed air after cleaning is complete.

After step two (2) above is complete, the liner seal rings can be installed on the liner At this time lubricate the lower cylinder block bore and the seal rings with a rubber lubricant, liquid soap or silicone grease. Do not use any type of spray silicone. Completely coat the black filler band with clean engine oil and install in the upper band groove At this time the liner must be installed in the cylinder block as the black filler band is designed to swell upon contact.

Caterpillar 3406E Cylinder Head Torque Procedure

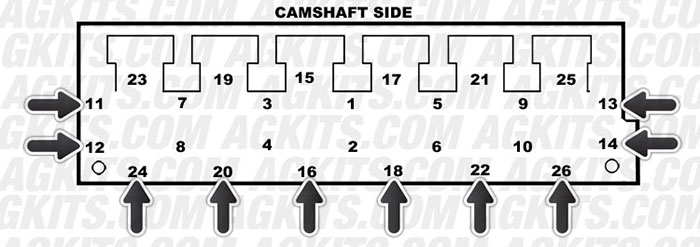

Head bolts marked with arrows are 216mm (8.5") long. The other bolts are 194mm (7.6") long. It is recommended to use a moly paste (Caterpillar # 6V4876) on all bolt threads. Without it you will not reach the proper torque value.

1. Torque bolts 1 through 26 (in sequence) to 200 ft/lbs (plus or minus 11 ftlbs)

2. Torque bolts 1 through 26 (in sequence) to 333 ft/lbs (plus or minus 15 ftlbs)

3. Torque bolts 1 through 26 (in sequence again) to 333 ft/lbs (plus or minus 15 ftlbs)

*Cylinder Head deck straightness should be within .13mm (.005") overall. The maximum warp spec is .03mm (.001") over any 76.2mm (3.00") span.

|

|

|